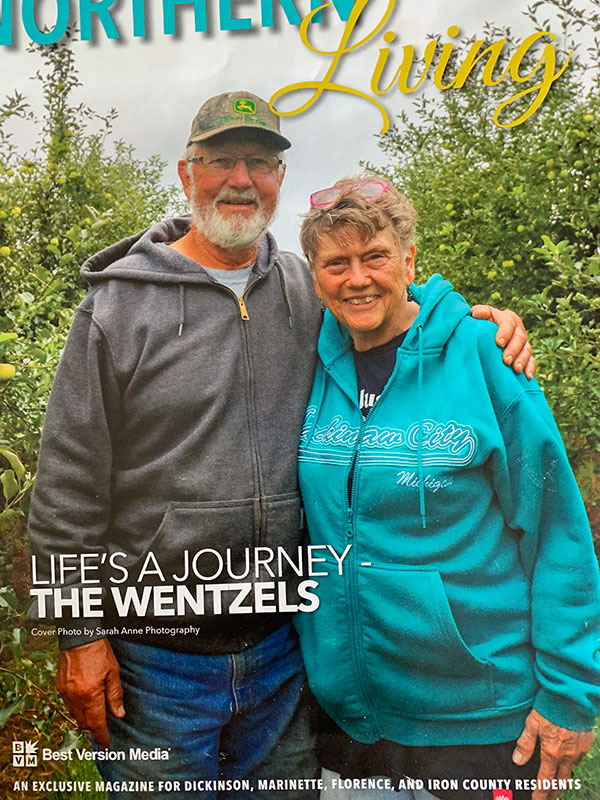

In our opinion, Hal and his wife, Carol, are pretty much the Eighth Wonders of the World(!) Twenty years ago, they started a little retirement business: growing apples (his part) and baking with them (her part). Now, they have a prosperous business with thousands of trees and a seasonal commercial bakery.

It is amazing that they have accomplished all of this in their retirement, but it is even more amazing because of two major challenges they faced in 2010, just eight years after they broke ground.

The first challenge was that the orchard froze during bloom and only 15% of the crop survived.

The second challenge was that during an already incredibly difficult time, Carol contracted leukemia and almost died. She was in the hospital for nearly 70 days and relied upon family and friends to keep the bakery business going.

With a lot of prayers they made it through that year and now, incredibly, Carol is 100% cancer-free. And, they are still running and continually growing the business!

This photo appeared on the cover of Northern Living, a regional magazine, along with an article about Hal and his wife, Carol. It was published in October, 2019.

Hal’s Story

Growing up, I was always fascinated by science and math at a time when computers were just beginning to make their mark in the world (late 50’s – early 60’s).

After graduating from UW-Madison with a degree in math and after military service and a few other occupations, I started my own computer programming business. I continued this into my 50’s. At that point, I knew I was ready for a change. I wanted to move on from my computer career.

I had always enjoyed growing things and believed running an apple orchard would give me something active to do in my traditional “retirement years.”

That was twenty plus years ago when we purchased twenty acres of farm field in Northeast Wisconsin on the border with Michigan’s Upper Peninsula. We began by planting 180 trees, and now have a thriving apple business with about 2,500 trees across twenty plus cultivars (varieties).

We also have 1/4 acre of blueberries and a few plum trees.

In addition to the orchard and bakery, for thirty-plus years we made maple syrup …

… and for roughly ten years we collected honey from our own bee hives.

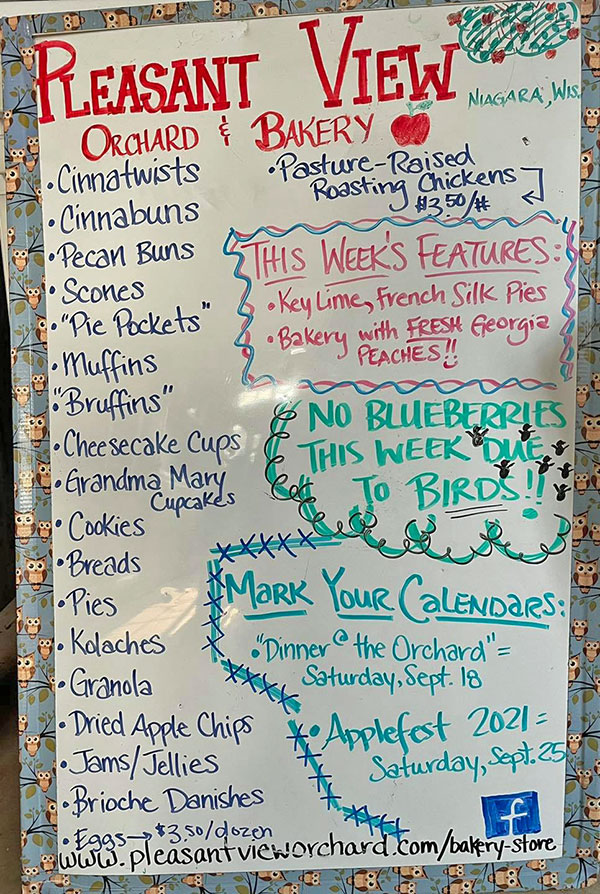

My wife, Carol runs the bakery side of the business.

My wife, Carol runs the bakery side of the business.

Carol currently makes at least a dozen plus types of made-from-scratch breads. She even grinds her own wheat.

We raised three children, and also have 17 grandchildren and one great grandchild. Throughout it all, God has graciously given us these opportunities and blessed us immensely.

This photo is taken every few years with the same pose. It shows fifteen of our seventeen grandkids.

Each year, I have to prune all 2500 apple trees by hand. (I have some help but I do 90% of it myself.) Here, some of our grandkids were helping me burn the prunings.

In 2007, our son who was a medical doctor became disabled by encephalitis and moved in with us. To help with his recovery, we decided to raise some animals.

Over the next few years, we acquired chickens, sheep, pigs and dairy goats.

Andy’s wife, Sara with Franz, an orphaned baby lamb who had just lost his twin brother and needed extra care. (His collar looks tight, but that’s just because Sara was holding on to him to keep him from falling off the gator.)

We started with two Oberhasli does and are now milking six.

Bella, the all-time favorite mama who, sadly, passed away this February, 2022 due to complications from childbirth.

We love the Oberhasli, which originated in the Swiss Alps, with their sweet, friendly disposition. Their milk is fantastic, too.

Goat kids and “runner ducks.” The ducks travel everywhere on our property and never have to be fed. They just find what they can and often steal the other animals’ feed.

Soon, we had excess milk, and that’s when the idea of cheese making was born. It was only a couple of years ago.

I had been researching cheese making on the internet, and discovered a store in Madison, Wisconsin, that sold cheese making supplies.

We stopped there on one of our trips and it opened my eyes as to the possibilities of cheese making with our milk. We bought some cheese making equipment and a few cultures.

This shows my double boiler (it holds 3.5 gallons) for heating milk during the initial stages of the cheese making process. I don’t have to worry about scalding the milk and it holds the temperature well. In this photo I have started a batch of butterkase.

I made this rig to flip my cheese while it’s draining. Pictured is Saint Marcellin made with our raw goat milk. Prior to using this system, I flipped the cheese by hand, which was an incredibly messy (and sometimes disappointing) process.

Here’s another tool I made that I use for pressing my cheese. I can control the pressure on the cheese by adding various weights at different distances from the fulcrum.

My cheese cave. It is a refrigerator. Notice the rags hanging over a container of water. The rags wick the water up to maintain humidity. The best I can do is about 60%.

Our first cheese was chèvre. In my internet searches, I discovered New England Cheesemaking Supply (cheesemaking.com) and their wide selection of cheese recipes. I continue to try different recipes to the enjoyment of my family.

Thus far, I have made Brie, Camembert, Cam-Bleu, Swiss, Havarti, Saint Marcellin, brick and cheddar. I make cheese dependent on my workload.

Up until a couple weeks ago, I had time on my hands, so I made maybe one batch a week. Now, I’m very busy tending to the orchard as apple season progresses, and therefore do not have as much free time to make cheese.

Some of my cheddar. I made it about a year ago. We tried it last fall and it was terrible. We just tried it again, and it is fantastic – very sharp. My wife said no more cheddar from the store. You can see that I had waxed it.

We have been getting about seven gallons per day for about 9 months in the year.

Our cream separator. I use this primarily for making goat butter, which I now eat exclusively. I no longer consume dairy products from cow’s milk, and I also believe that raw goat’s milk and products from it have been good for my health.

The goats dry off after breeding season in Autumn, and start up again after giving birth in Spring. The fat content of their milk increases as the year progresses, so I like to make butter mostly in the fall.

My son recently has been diagnosed with Lyme disease and co-infections, so he has to reduce his workload and thus we are downsizing our goat herd.

But, we won’t be cutting the herd down to the point where I won’t be able to make cheese.

My goal is to continue experimenting by making all the different cheeses which appeal to me. Long-term, I’d like to then narrow down that list of cheeses I’ve made and only invest time in making the cheeses I really love.

Pleasant View Orchard and Bakery

W6050 Chapman Road

Niagara, Wisconsin 54151

Call only: (715) 927-2450

Text or call: (320) 361-0112

Website – pvobapples@gmail.com

Facebook – https://www.facebook.com/PleasantViewOrchardAndBakery/

Iron Mountain Outdoor Farmers Market (June – October)